Micro AM for Microfludic Devices

Microfluidic devices are widely used in healthcare, biological, and medical fields. They are also finding increasingly diverse applications in environmental analysis, as well as food and agriculture research.

Contact SalesMicro AM for Microfluidic Devices

Microfluidic devices are widely used in healthcare, biological, and medical fields. They are also finding increasingly diverse applications in environmental analysis, as well as food and agriculture research. The functionalities and performances of microfluidic devices are highly dependent on the methods of fabrication, the skill of the engineer, and the materials used to construct the constituent components.

Traditionally, microfluidic devices are fabricated by soft lithography, a process where features are moulded in elastomers such as polydimethylsiloxane (PDMS). Making a microfluidic device requires several hours of intensive labor. Microfluidic device needs to be cut first into layers and then bond each layer together again to make a functional device. Injection molding can be used in manufacturing, while the mold often costs high and delivery time can be months. Also due the limit of CNC, design with diameters less than 100 microns and with high aspect ration cannot be reached.

Why Micro 3D Printing

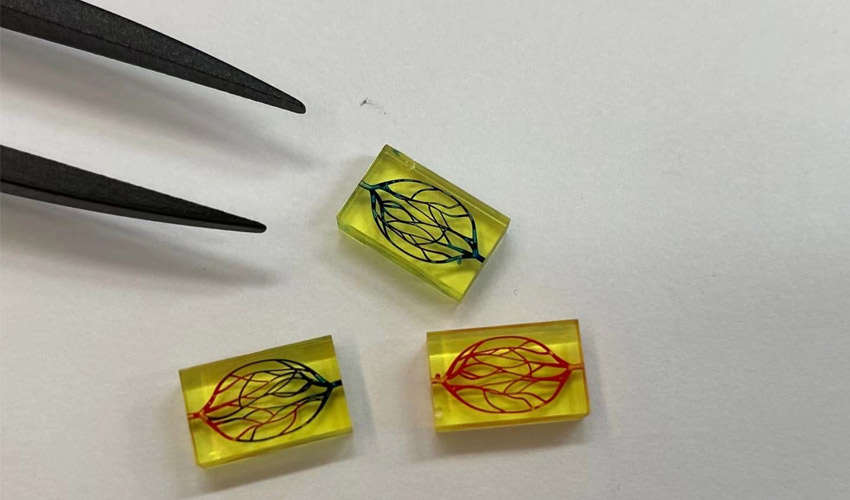

3D printing is a good way to solve the issue of mold making with high cost and long turnaround time. But only micro 3D printing meets the challenge to make parts below 100microns. Advantages of using micro 3D printing for microfluids devices are:

- More design freedom and intricate details of 20microns can be printed. Designs of high aspect ration is not a problem with micro AM.

- Material with high temperature durance and good biocompatibility is available.

- Batch production is feasible, manufacturing time can be dramatically reduced.

- Printed micro parts can be used to support PDMS mold making.

Success cases like fluids connector, valve have been successfully printed by SteraFab. Reach to SteraFab for your micro cases.

What material works best for