Micro AM for MEMS

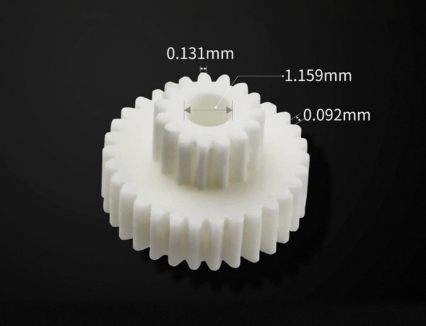

Mechanical parts include springs, gears, connectors, sockets, and brackets required in precision mechanics or electronics. Parts are widely used in robotics and industrial applications.

Contact SalesMicro AM for MEMS (Micro-Electro-Mechanical Systems)

SF-V40 High toughness resin;SF-HT210 High temperature resin

MEMS generally refer to electrical devices fabricated in micrometer range and any moving parts inside are in the range size of µm. Mechanical parts include springs, gears, connectors, sockets, and brackets required in precision mechanics or electronics. Parts are widely used in robotics and industrial applications.

MEMS product development is becoming faster. The smaller the parts go, the cost and challenge increases. Mold making for such parts often result in spending long time and more money waiting for the mold. And there’s possibility that the mold will be discarded because of design changes.

Why Micro 3D Printing

Micro 3D printing eliminates the tooling used in micro injection molding and can reduce time-to-market across multiple design iterations and test cycles. Advantages are listed below.

- Design versatility. 3D Microfabrication enables you to create complex micromechanical parts with submicron resolution and up to millimeter sizes.

- Time and money saving.

Reach SteraFab for your micro cases.

What material works best for