Micro AM for PDMS

Contact SalesMicro AM for PDMS

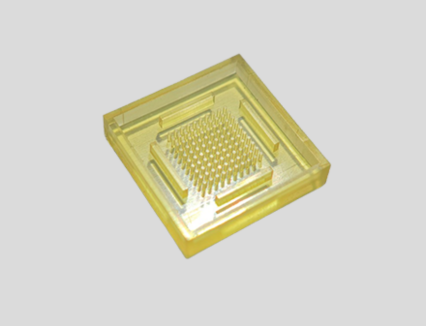

Polydimethylsiloxane, called PDMS, is a polymer widely used for the fabrication and prototyping of microfludics, microneedles, optics, electronics, architecture, and emerging sustainable energy related applications.

Why Micro 3D Printing

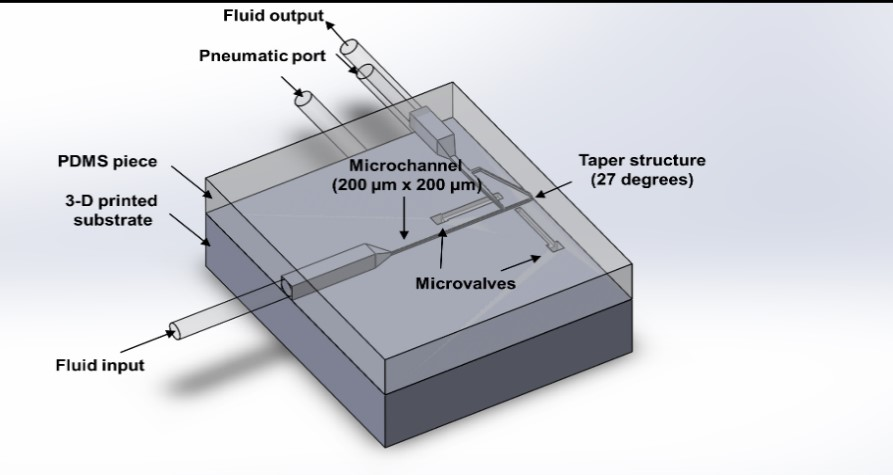

Taking microfludic chip for example, to make microfluidic chip prototypes using polydimethyl siloxane (PDMS) to cast the target microstructure is a standard procedure in microfluidic manufacturing. But, manufacturing the according moulds by micro-milling from polymers like polymethylmethacrylate (PMMA) is a time-consuming process. Furthermore, certain structures cannot be milled directly, and the surface quality of fast micro-milled polymer parts is not sufficient for adequate moulding of PDMS, making slow infeed and special cutting tools necessary. Metal as mould material as well as the use of special diamond-milling-tools can improve the surface quality but increase the manufacturing costs significantly at the same time.

3D printing is an attractive method to fabricate microfluidic devices due to (1) its fast and simple process without specialized equipment and cleanroom environment, and (2) its capability to create complex 3D structures. Combined with Polydimethylsiloxane (PDMS), it can be used to develop various microfluidic devices taking advantage of both 3D printing and PDMS.

There are two criteria that a mould must fulfil: the PDMS cast must be retractable residue-free, and the functionality of the final microfluidic system must be given. For the latter a sufficient shape accuracy must be reached, and the casted observation channel must be transparent. For structures < 250 µm, Micro AM is one of the few 3D printing technologies to fulfil the needed shape accuracy. Furthermore, the production time of all AM processes were significantly faster than the micro-milling process due to the required slow feed speed and mould-copying-process.

What material works best for