The 3D printing industry is growing rapidly, with the use of metal materials on track for a CAGR of 24% through 2030. Parallel to this growth is the US metal casting market, expected to reach around $23 million by 2025. This expansion continues to drive demand for 3D printed molds in applications ranging from automotive to custom jewelry. With the launch of our new cast metal finishes, Shapeways is excited to deepen our commitment to providing our customers with an expansive material and finish offering.

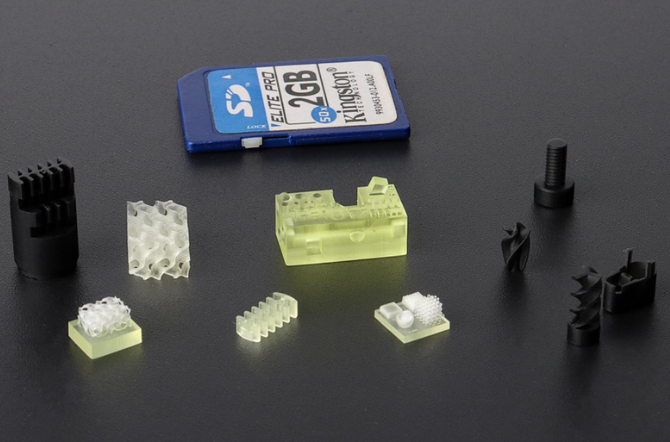

Shapeways’ metal casting technology (also known as wax casting) combines the speed of 3D printing with the durability and finish of traditional metals. Beyond faster production and higher accuracy, metal casting allows for more intricate shapes. To get a quote in one of our new cast metal finishes, upload and print your file here.

New Brass Cast Metal Finishes

Brass, a copper alloy that consists of 80% copper, 15% zinc, and 5% tin, is known for its intricate detailing and professional finish. This material is commonly chosen for applications ranging from jewelry to home decor.

14K Yellow Gold Plated Brass (now available in 3 μm as well as 0.5 μm) is visually stunning and highly durable. Recommended for products like fine jewelry and detailed miniatures, this material offers a luxurious look without compromising integrity.